The International Magnesium Association (IMA) announced the findings of a comprehensive material flow analysis of magnesium in the EU for the year 2012. The report, Magnesium Recycling in the EU (pdf), was prepared during the first half of 2017 by Oakdene Hollins on behalf of the IMA and was based on valuable input received from both industrial and academic stakeholders during the three month study. The materials flow analysis demonstrates the importance of Mg to the EU economy and everyday products such as aluminum beverage cans, auto and aerospace, consumer electronics, and steel.

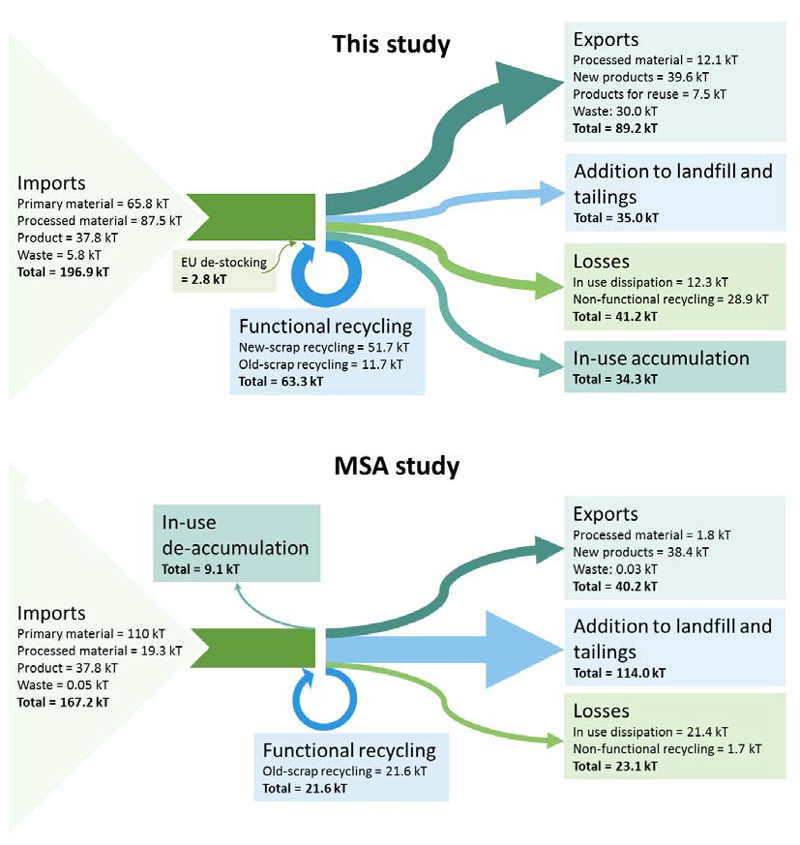

This study’s findings are intended to supersede those presented for magnesium (metal) in the Material System Analysis (MSA) study, titled “Study on Data for a Raw Material System Analysis: Roadmap and Test of the Fully Operational MSA for Raw Materials,” produced for DG-GROW in 2015. While alternative data sources were sought and estimates refined, the overall approach to the material flow analysis employed for the Magnesium Recycling in the EU study was the same as in the MSA study in terms of flows, notations and definitions. The results of both studies were therefore compared like-for-like. However, given that Magnesium Recycling in the EU study focusses on one material only, while the MSA study covered the 21 materials (or families of materials) identified as critical to the EU, this study is able to go into much more detail on individual streams.

The main differences in the findings of this study compared to those reported in the MSA study are:

- This study finds the figure for Mg imports into the EU is 18% higher than reported in the MSA study.

- This study finds exports are over double those identified in the MSA study.

- Landfill in the EU is only 30% of that identified in the MSA study.

- The MSA study includes only old scrap functional recycling, while this study also quantified functional recycling of new scrap.

- Non-functional recycling of Mg is an order of magnitude higher than in the MSA study,

- Instead of 9,000 tonnes of de-accumulation as in the MSA study, this study found there were 34,000 tonnes of in-use Mg accumulation.

As with the MSA study, one key output of this work is a high-level Sankey diagram (Figure 1) of the inputs and end-fates of magnesium (metal) in the EU. Even a brief inspection of the diagram highlights some of the main differences in the findings of this study compared to those reported in the MSA study.

The End of Life – Recycling Input Rate (EOL-RIR), which measures the percentage of magnesium coming from EOL scrap in the total amount of magnesium entering the EU, was also derived from the material flow analysis data. At 7%, the EOL-RIR of Mg is low — lower than that of Al at 12% (global, not EU specific value). This was not unexpected given the dispersive nature of some of Mg’s applications, and the collection and recycling inefficiencies.

The main improvements in collection and recycling efficiencies that could increase the recycling rate of Mg are:

- Greater dismantling of Al and Mg alloy components from ELVs (average of 4.1 kgs of magnesium in a car built in 2012 including magnesium in aluminum alloys).

- Even higher collection rate of End of Life aluminum beverage cans (average magnesium content: 1.6%).

- Technological advances in the automated sorting of Al alloy fractions from shredding.

- Diverting more high Mg-containing Al alloys to remelters, who generally try to retain the Mg in their input materials, rather than by refiners, who do not.

- Diverting more segregated End of Life Mg alloys to specialist Mg recyclers.

- Better slag utilization by the Al and steel industries (non-functional recycling only).

This list highlights the fact that the recycling rate of Mg is very dependent on the activities of the aluminium and, to a lesser extent, the steel industries. Identifying best practice for Mg retention in Al alloy recycling requires further investigation in order to identify more targeted opportunities for its improvement. The IMA noted that it would also be interesting to calculate what the maximum realistic recycling rate of Mg would be in the EU if current, and forecast, best practice methods for Mg retention were fully implemented.