To say that 2020 has been an interesting year would be a massive understatement. Throughout this wild ride of a year, Light Metal Age (LMA) has been proud to be a valuable resource, providing industry news and technological insights to its readers. On the LMA webpage, we regularly share exclusive featured articles from the print magazine, as well as timely news on technology and manufacturing developments in extrusion, rolling, casting, smelting, recycling, and more.

As we near the end of the year, we enjoy looking back on LMA’s top ten most viewed news stories that were published on our website in 2020. This year’s list of most viewed stories provides fascinating insight into the trends that have affected the aluminum sector.

The Impact of COVID-19

It’s no surprise that the biggest news of 2020 has been the COVID-19 pandemic and its impact on industry and the world at large. The aluminum industry has largely remained an essential business, weathering the challenges of shelter-in-place orders and supply disruptions.

Union Sheet Metal Workers Team Up to Produce Free Aluminum Nose Pieces for Face Masks — Our story on how sheet metal workers were teaming up to support the production of face masks in a time of scarcity garnered the most interest this year — by far. As the story notes, a number of aluminum sheet operations banded together to manufacture free nose pieces for use in N95 and N99 masks desperately needed by medical care professionals working on the front line of the pandemic.

Union Sheet Metal Workers Team Up to Produce Free Aluminum Nose Pieces for Face Masks — Our story on how sheet metal workers were teaming up to support the production of face masks in a time of scarcity garnered the most interest this year — by far. As the story notes, a number of aluminum sheet operations banded together to manufacture free nose pieces for use in N95 and N99 masks desperately needed by medical care professionals working on the front line of the pandemic.

Aluminum Response to the Novel Coronavirus Crisis — A follow up article published in May provided a wider scope of the aluminum industry response to the pandemic. The article highlights aluminum’s role as an essential industry, looking at the economic impact of the pandemic, and provides insight into how a number of aluminum companies approached the challenge of keeping their workers safe.

Importance of Sustainability

In the face of climate change, consumers and businesses alike are becoming more and more focused on sustainability. A key focus of the aluminum industry has been and continues to be the need to address the environmental challenge inherent in the energy intensive aluminum smelting process. Two of our top viewed articles published this year focused on how the industry is working to improve the sustainability of primary aluminum.

Update on the Aluminum Industry Response to Climate Change by John Grandfield, Grandfield Technology — Climate change has brought the greenhouse gas (GHG) emissions of aluminum smelting into sharp focus. Other important sustainability issues include bauxite residue dam integrity, waste disposal (spent potling, dross, etc.), water consumption, working conditions, bio diversity, etc. In this article, Grandfield examines past work to reduce GHG emissions along with latest trends within the industry around “green” low CO2e aluminum marketing and certification. The prospects for renewable energy replacement of fossil fuel power by solar generated water splitting to obtain hydrogen are discussed in the context of the Australian energy policy.

Update on the Aluminum Industry Response to Climate Change by John Grandfield, Grandfield Technology — Climate change has brought the greenhouse gas (GHG) emissions of aluminum smelting into sharp focus. Other important sustainability issues include bauxite residue dam integrity, waste disposal (spent potling, dross, etc.), water consumption, working conditions, bio diversity, etc. In this article, Grandfield examines past work to reduce GHG emissions along with latest trends within the industry around “green” low CO2e aluminum marketing and certification. The prospects for renewable energy replacement of fossil fuel power by solar generated water splitting to obtain hydrogen are discussed in the context of the Australian energy policy.

Primary Aluminum: Inert Anode and Wettable Cathode Technology in Aluminum Electrolysis by Joseph C. Benedyk, Editor — Each month, LMA features a selection of international patents showcasing the research and development work being undertaken in the aluminum industry. Our patents selection from February 2020 focused on wettable cathode technologies for aluminum smelting. As Benedyk notes in his introduction, wetted cathode technology offers an opportunity to reduce energy consumption, as well as providing additional environmental and production enhancing benefits.

Automotive Market

Despite the challenges presented by COVID-19, the automotive industry is expected to maintain its strong demand for aluminum sheet and extruded profiles. The DuckerFrontier report published this year notes that aluminum content is expected to grow to 514 lbs per vehicle by 2026, up by 12% from 2020 levels. Key growth areas include aluminum sheet used in closures (hoods, doors, etc.), body-in-white, and chassis applications, as well as an increase in the production of electric vehicles.

With automotive aluminum continuing its growth trajectory, it’s understandable that three of our top articles from 2020 would be focused on the automotive market, highlighting future trends and investments designed to meet demand.

The Coming BEV Wave: Implications for Extrusion by Lynn Brown, Consulting Collaborative, and Rob Nelson, Almag Aluminum — In this article, the authors examine the technologies required for the future of growth of battery electric vehicles (BEVs), which are expected to reach sales in the vicinity of 1 million units per year (about 6% of the market) by 2025 in North America. Aluminum extrusions have a role to play in the BEVs of the present and future in regards to lightweighting, battery system housings, and thermal management of the battery.

The Coming BEV Wave: Implications for Extrusion by Lynn Brown, Consulting Collaborative, and Rob Nelson, Almag Aluminum — In this article, the authors examine the technologies required for the future of growth of battery electric vehicles (BEVs), which are expected to reach sales in the vicinity of 1 million units per year (about 6% of the market) by 2025 in North America. Aluminum extrusions have a role to play in the BEVs of the present and future in regards to lightweighting, battery system housings, and thermal management of the battery.

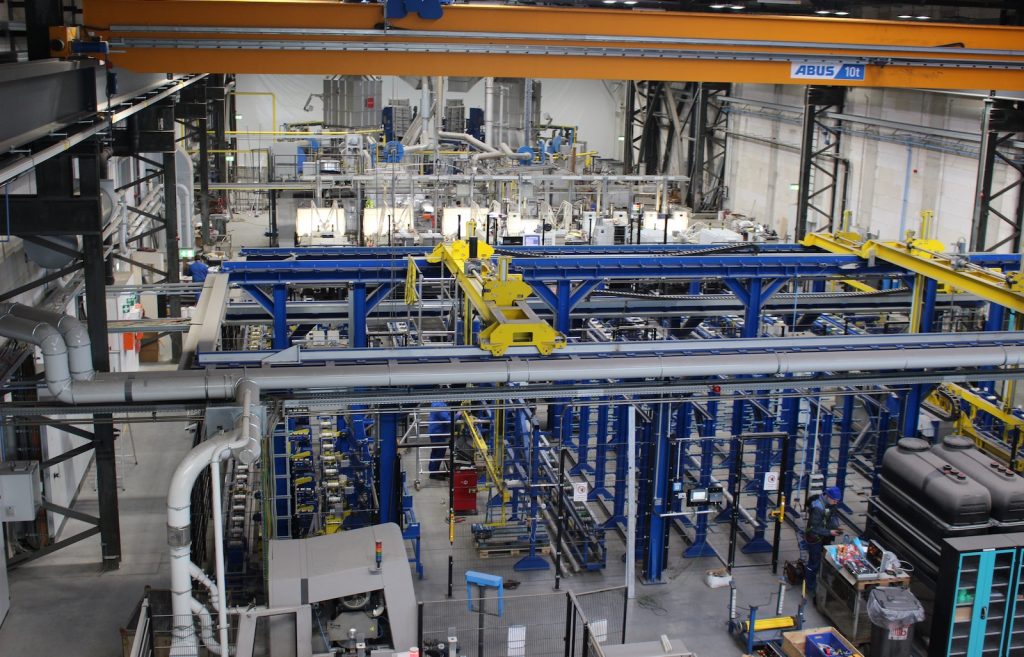

Bharat Forge Aluminiumtechnik Expands with State-of-the-Art Horizontal Casting Machine by Lutz Müller, Bharat Forge Aluminiumtechnik, and Robert B. Wagstaff, Oculatus — Bharat Forge Aluminiumtechnik (BF-AT), located in Brand-Erbisdorf, Germany, completed the construction of a new melting and casting facility in 2019. The facility was designed to produce forging billet to serve the automotive forging market. This article presents an overview of the expansion project at the Brand-Erbisdorf facility, with information on its new process capabilities and capacity. In addition, it offers insight into the key metrics considered during the planning stage and some of the technological hurdles overcome during the journey.

Rusal Commissions Ingot Casting Line for Automotive — Aiming to increase its production of value-added products, UC Rusal started up a new ingot casting complex at the Boguchansky smelter with a capacity of 120,000 tonnes of aluminum alloys per year. The new line produces a new alloy for Rusal, which is commonly used in the production of automotive wheels.

Rusal Commissions Ingot Casting Line for Automotive — Aiming to increase its production of value-added products, UC Rusal started up a new ingot casting complex at the Boguchansky smelter with a capacity of 120,000 tonnes of aluminum alloys per year. The new line produces a new alloy for Rusal, which is commonly used in the production of automotive wheels.

International Trade

This year faced a number of international trade cases, from ongoing concerns surrounding the implementation of 232 tariffs to various antidumping cases in a variety of sectors, including aluminum sheet and extrusions. Although only one of the news stories regarding trade made it on to our top ten list, there is no doubt that the subject of international trade is a subject that will continue to be hotly discussed in the months and years to come.

U.S. Aluminum Industry Files Unfair Trade Cases Against Imports of Aluminum Foil From Five Countries — The Aluminum Association’s Foil Trade Enforcement Working Group filed antidumping and countervailing duty petitions charging that unfairly traded imports of aluminum foil from five countries — Armenia, Brazil, Oman, Russia, and Turkey — are causing material injury to the domestic industry.

U.S. Aluminum Industry Files Unfair Trade Cases Against Imports of Aluminum Foil From Five Countries — The Aluminum Association’s Foil Trade Enforcement Working Group filed antidumping and countervailing duty petitions charging that unfairly traded imports of aluminum foil from five countries — Armenia, Brazil, Oman, Russia, and Turkey — are causing material injury to the domestic industry.

Aluminum Surface Treatment & Design

The last two articles in our top ten list focus on aluminum surface treatment and design — areas of manufacturing that are critical to aluminum’s role in market sectors such as architecture and other structural applications.

Pries Installs One of the Most Advanced Anodizing Lines in the U.S. by Rose Eaton, Staff Writer — Pries Enterprises finished a 50,000 sq ft expansion and installation of a state-of-the-art anodizing line, solidifying the company as a one-stop shop for extrusion, anodizing, and fabrication of aluminum. This article provides a look into the company’s history and an overview of its new anodizing line, as well as its new automated packing line. The fact that women make up a larger portion of workers at the facility is discussed.

Pries Installs One of the Most Advanced Anodizing Lines in the U.S. by Rose Eaton, Staff Writer — Pries Enterprises finished a 50,000 sq ft expansion and installation of a state-of-the-art anodizing line, solidifying the company as a one-stop shop for extrusion, anodizing, and fabrication of aluminum. This article provides a look into the company’s history and an overview of its new anodizing line, as well as its new automated packing line. The fact that women make up a larger portion of workers at the facility is discussed.

Aluminum Association Releases the 2020 Aluminum Design Manual — The newly updated 2020 Aluminum Design Manual is an essential reference for engineers, designers, detailers, and architects working with aluminum in structural applications.